Project #4

Kraft Canada Inc., Ottawa, ON

1995/1996

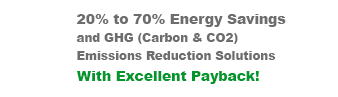

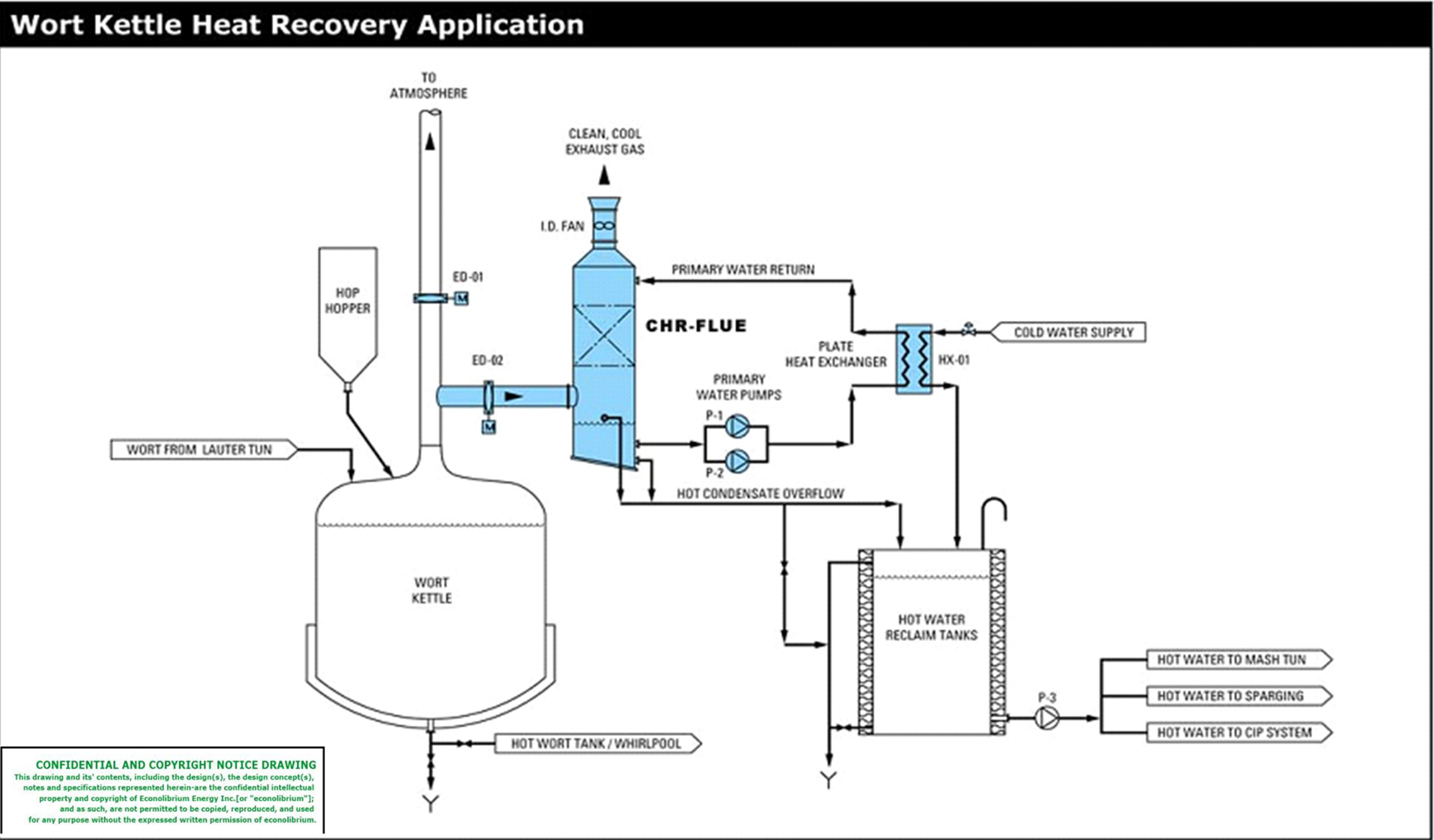

Food & Beverage Industry. Industrial Processes Vent Gases: Cookers/Steamers + Dryers, and Bunker C Oil Boilers Flue Gases Applications

- Two turnkey CHR-FLUE™ Systems installed:

- Hybrid for Minute Rice™ Process Dryers & Steamers

- NG+ No.6 Oil Boiler Plant exhausts

- 30 million Btu/h heat recovery rate for combined systems

- Recovery and reuse of 80% to 90% of the heat loss from dryers and boilers

- 25% to 30% reduction of natural gas and bunker oil consumption

- Annual savings over $450,000/Year (1996 unit energy cost), valued today at $1,125,000/Year

- Secured $600,000 Capital Grant from Ontario Ministry of Energy for partial funding

- Financial payback was 3.5 years (in 1996); however, Financial payback would be < 2 years – based on today’s 2.5 x higher NG Unit Cost