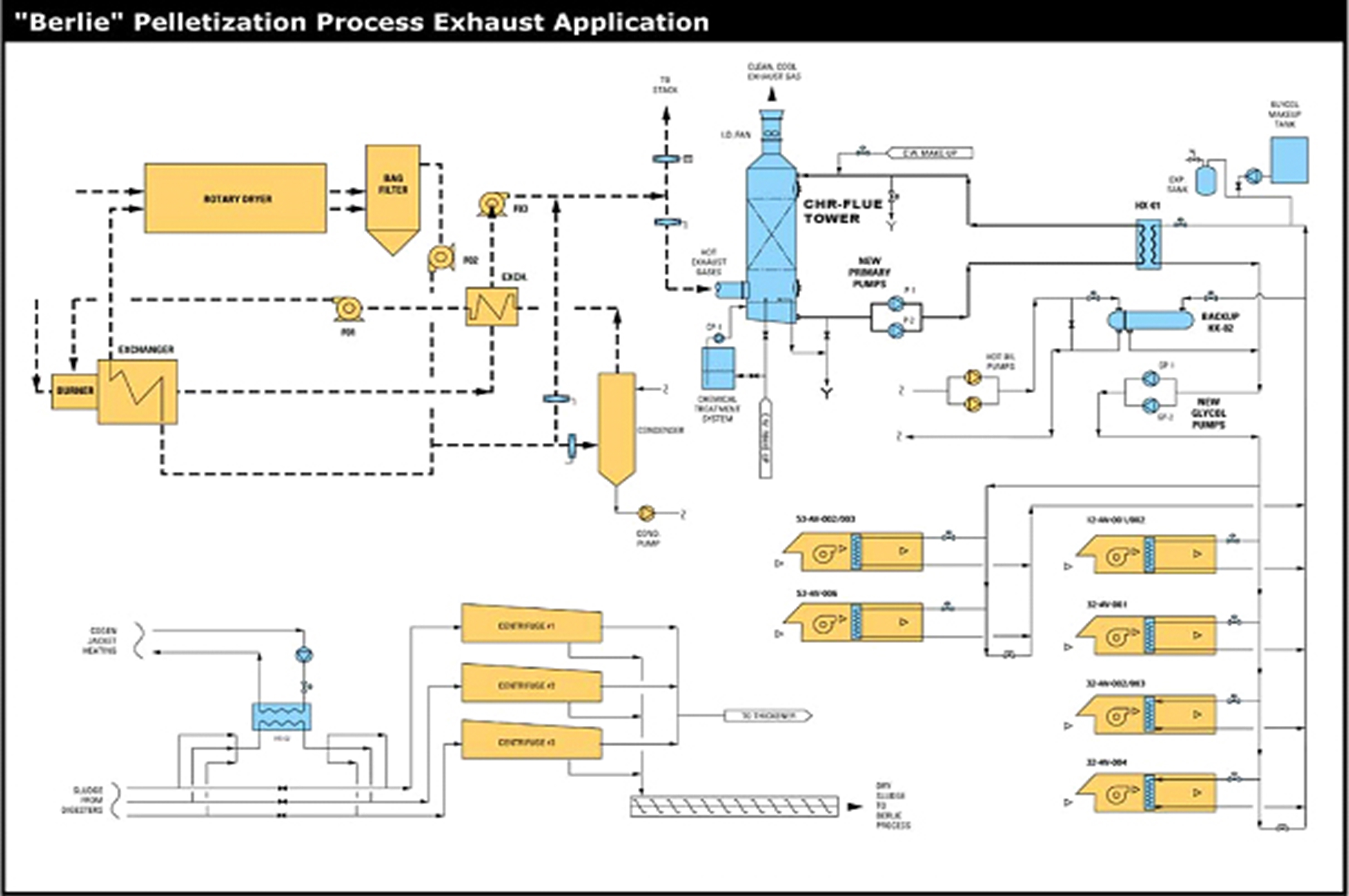

Project #6

Gatineau Sewage Plant, Gatineau, Quebec, Canada

Sewage Plant Boiler and Sludge Dryer Applications Gatineau Sewage Treatment Plant, Gatineau, Quebec, 1998

- 1998 – Hybrid CHR-FLUE™ for combined PM and VOC APC and HR from exhaust gasses emitted by sludge rotary dryer and fertilizer pelletization system. Heat recovered and recycled for continuous glycol heating of plant fresh air make-up HVAC units.

- Innovative Energy Efficiency & Process Optimization Measures implemented in the project:

- Sludge dryer burner retrofit to enable continuous use of recycled methane sewage plant gas

- Custom heat exchanger for preheating sludge before centrifuges, to improve de-watering efficiency by 30%

- 1 MW engine cogeneration system retrofitted for natural gas/dieselfuel operation

- 25% to 30% reduction of natural gas and methane consumption

- Annual savings $250,000 with financial payback in 3.5 years (in 1998); however, based on todays 2 x higher NG costs, it would be < 2.5 Years payback