Project #3

Gatineau Hospital, Gatineau, Quebec, Canada

2008/2010

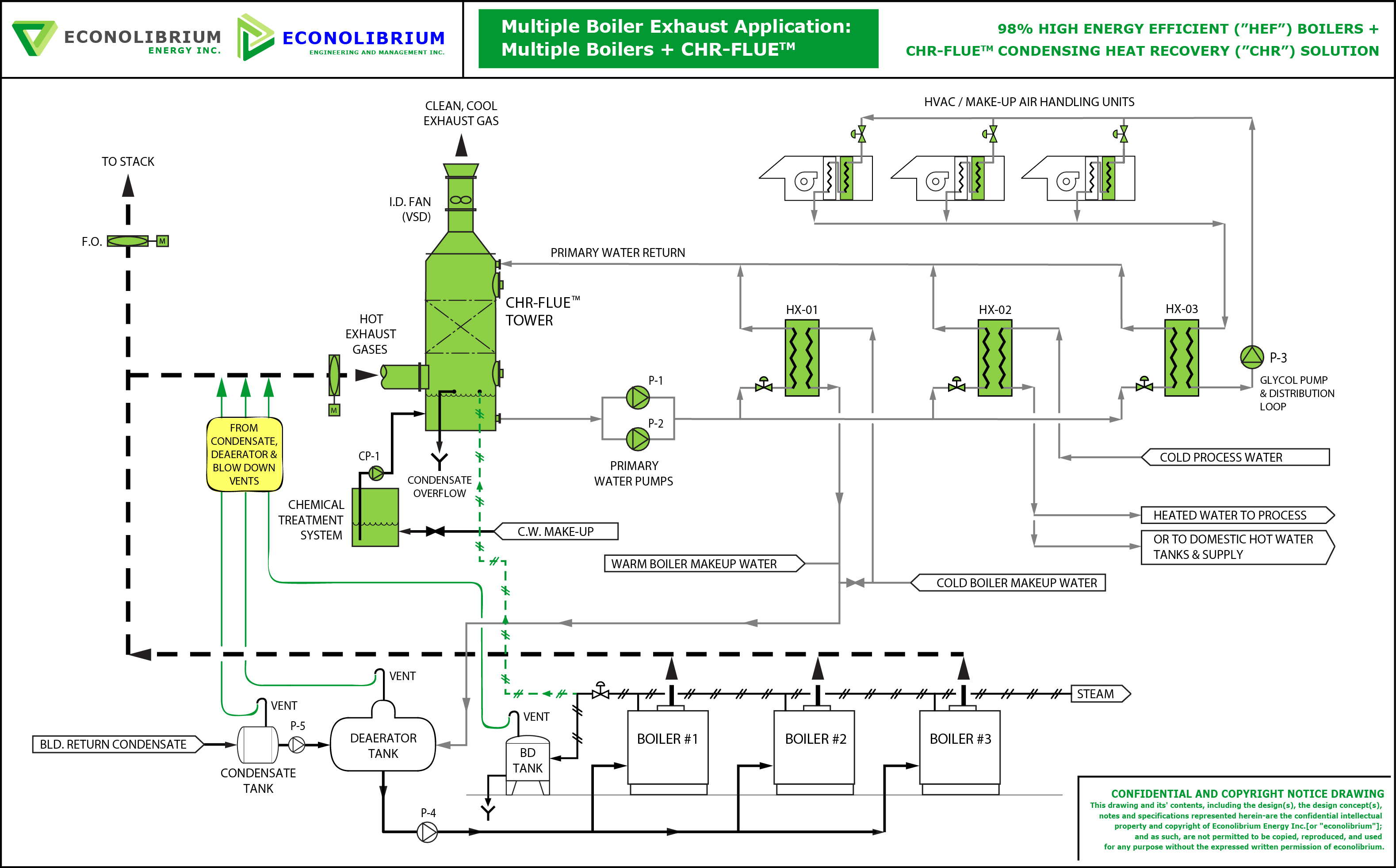

- The new CHR-FLUE™ condensing heat recovery system was engineered and constructed by retrofitting the old 1989 Standard CHR System – to achieve greater than 98% boiler plant energy efficiency, increase $ savings, improve operating reliability, increase automation, and to make more “user friendly” and “fail safe”

- SMART Boiler-CHR-Economizer-&-HVAC Efficiency Monitoring and Control System; to integrate and synchronize all energy systems, and to continuously monitor and control energy efficiencies at maximum levels. Also includes new “ALARM MESSAGES” to notify operator when necessary to ensure optimum performance and operation.

- The new CHR-FLUE™ includes a new triple boiler smoke stack combined SST round ductwork manifold c/w emergency by-pass SST smoke stack to safely and effectively control the boilers flue gases static pressure

- Expanded heat recovery system to heat HVAC reheat systems in Spring, Summer, & Fall

- The CHR-FLUE™ peak heat recovery rate: 5.5 million Btu’s per hour (or “mmBTU/h”)

- Reduction of new Miura (Coil Tube) steam boilers fuel (natural gas and oil) consumption by over 20%

- Recovery and recycling of over 95% of waste heat from boilers flue gases

- Financial Payback was 3.2 years based on 2007 dollars